Precision and efficiency are two critical factors that drive success in modern manufacturing and engineering processes. As industries demand tighter tolerances and flawless surface finishes, specialized machinery plays a key role in meeting these requirements. One such essential machine is the external cylindrical grinder, a tool designed for shaping and finishing the outer surfaces of cylindrical components. This equipment has become indispensable across a wide range of sectors, from automotive and aerospace to medical devices and heavy machinery. Its adaptability, accuracy, and productivity make it a cornerstone of modern manufacturing processes internal cylindrical grinder.

Understanding External Cylindrical Grinders

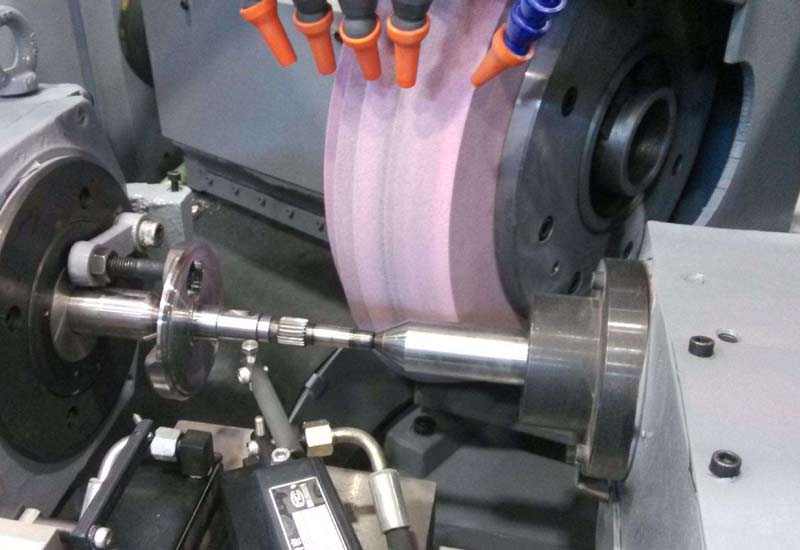

An external cylindrical grinder is a type of grinding machine designed to remove material from the external surface of a cylindrical workpiece. It employs an abrasive wheel that rotates at high speed while the workpiece is simultaneously rotated and fed against the grinding wheel. This dual action ensures even removal of material, resulting in precise dimensions, excellent surface finish, and superior roundness.

These grinders are versatile and can work on various materials including steel, aluminum, titanium, ceramics, and even advanced composites. They are commonly used to create smooth, accurate, and wear-resistant surfaces, which are critical for parts that must perform reliably under demanding conditions.

Key Features of External Cylindrical Grinders

External cylindrical grinders stand out due to their unique features that enhance precision and performance.

- High Accuracy: Capable of achieving tight tolerances down to microns.

- Surface Quality: Produces smooth finishes that reduce friction and wear.

- Versatility: Handles a wide range of workpiece sizes and materials.

- Automation Options: Many modern grinders come with CNC controls for automated, repeatable operations.

- Durability: Designed to withstand continuous use in high-volume production environments.

Applications in the Automotive Industry

The automotive sector relies heavily on external cylindrical grinders to produce critical engine and transmission components. For example, crankshafts, camshafts, and gearbox shafts all require precise external surfaces to function effectively. These parts must endure constant motion, friction, and stress, making surface accuracy and finish crucial.

Additionally, bearings and axle components benefit from the fine finishes produced by grinding. By ensuring that surfaces are smooth and uniform, external cylindrical grinders contribute to better fuel efficiency, reduced wear, and longer vehicle lifespan. As electric vehicles gain popularity, the demand for high-precision rotating components has further highlighted the importance of this grinding technology.

Applications in the Aerospace Industry

Aerospace engineering demands some of the most stringent quality standards. Aircraft engines, landing gear systems, and structural components must be lightweight yet extremely durable. External cylindrical grinders play a vital role in achieving these goals.

Turbine shafts, hydraulic actuators, and aerospace bearings require extremely tight tolerances and surface finishes to ensure safety and performance under extreme conditions. The ability of these grinders to process exotic materials like titanium and high-strength alloys makes them indispensable in aerospace manufacturing. Furthermore, consistent grinding results help minimize vibration, noise, and wear in aircraft systems, enhancing overall flight safety and efficiency.

Applications in the Medical Industry

In the medical sector, precision is non-negotiable. External cylindrical grinders are extensively used in the production of surgical instruments, orthopedic implants, and dental tools. For instance, components like hip joint replacements, bone screws, and surgical drills must have flawless surfaces to prevent infections and ensure patient comfort.

Grinding ensures not only dimensional accuracy but also the smoothness required for biocompatibility. Since many of these devices are made from stainless steel, titanium, or cobalt-chrome alloys, external cylindrical grinders provide the necessary flexibility to handle different materials with ease. Moreover, CNC-controlled grinders allow for repeatable and consistent results, which is crucial for medical device manufacturers.

Applications in the Heavy Machinery Industry

Heavy machinery such as construction equipment, agricultural machines, and industrial turbines rely on robust cylindrical parts that can withstand high stress. External cylindrical grinders are used to manufacture shafts, rollers, and large bearings that must function reliably in challenging environments.

In these applications, durability and wear resistance are paramount. Grinding provides the precise geometry needed to ensure proper alignment and smooth operation of mechanical systems. By improving the quality of large rotating components, grinders contribute to longer service life and reduced downtime of heavy machinery.

Applications in the Tool and Die Industry

Tool and die making is another sector where external cylindrical grinders demonstrate their value. Cutting tools, punches, dies, and molds often require extremely tight tolerances and perfect finishes. Grinding is used to sharpen tools and refine surfaces, ensuring high performance in machining and forming operations.

For example, drills, reamers, and end mills benefit from cylindrical grinding to maintain cutting edge accuracy and improve longevity. In die manufacturing, accurate grinding ensures that the molds produce consistent and high-quality parts for industries ranging from plastics to consumer electronics.

The Role of CNC Technology in Cylindrical Grinding

The introduction of CNC technology has revolutionized the use of external cylindrical grinders. Computerized controls allow operators to program complex grinding operations with high repeatability. This automation reduces human error, increases productivity, and enables cost-effective production even for small batch sizes.

CNC grinders also offer flexibility, as they can switch between different part designs with minimal setup time. This adaptability is particularly valuable in industries that produce custom or varied components, such as aerospace and medical manufacturing.

Benefits of External Cylindrical Grinders Across Industries

The widespread adoption of external cylindrical grinders can be attributed to the numerous benefits they provide, including:

- Enhanced Product Quality: Produces superior finishes and precise dimensions.

- Cost Efficiency: Reduces scrap and rework through accurate machining.

- Extended Component Life: Smooth surfaces minimize friction and wear.

- Increased Productivity: CNC integration enables faster and more reliable operations.

- Material Versatility: Effective on metals, alloys, ceramics, and composites.

Future Trends in Cylindrical Grinding

As industries continue to evolve, external cylindrical grinders are also advancing with new technologies. Some emerging trends include:

- Integration of AI and Machine Learning: For predictive maintenance and process optimization.

- Eco-friendly Grinding: Development of coolant-free or minimum lubrication systems.

- Advanced Materials: Ability to handle next-generation composites and superalloys.

- Smart Automation: Real-time monitoring and adaptive control systems for improved efficiency.

These advancements will further strengthen the role of external cylindrical grinders in ensuring precision and reliability in modern manufacturing.

Conclusion

The external cylindrical grinder is more than just a machine tool; it is a cornerstone of precision engineering across multiple industries. From enhancing automotive performance to ensuring aerospace safety, from enabling medical innovations to powering heavy machinery, its applications are vast and indispensable. With the continuous integration of CNC, automation, and smart technologies, these grinders are set to become even more efficient and versatile. As industries push toward higher precision, sustainability, and productivity, the external cylindrical grinder will remain a vital asset in shaping the future of manufacturing.